The selection of Ball Valve should first follow the four principles of safety, reliability, applicability, and economy, and secondly, based on the six aspects of on-site working conditions.

1. Choose according to the length of continuous working time: normally closed, normally open, or continuously powered on

①If the opening time is short or the opening and closing time is not long, choose the normally closed type.

② However, for some working conditions used for safety protection, such as furnace and kiln flame monitoring, the normally open type cannot be selected, and the long-term energized type should be selected.

2. Select the Ball Valve according to the fluid parameters: material, temperature group

① Corrosive fluids: Corrosion-resistant Ball Valve and all stainless steel should be used; edible ultra-clean fluids: food-grade stainless steel Ball Valve should be used.

②High-temperature fluid: Choose a Ball Valve made of high-temperature resistant electrical materials and sealing materials, and choose a piston structure type.

③ Fluid state: It can be in gaseous, liquid or mixed state. Especially when the diameter is larger than DN25, it must be distinguished when ordering.

④ Fluid viscosity: Usually it can be selected arbitrarily below 50cSt. If it exceeds this value, a high-viscosity Ball Valve must be selected.

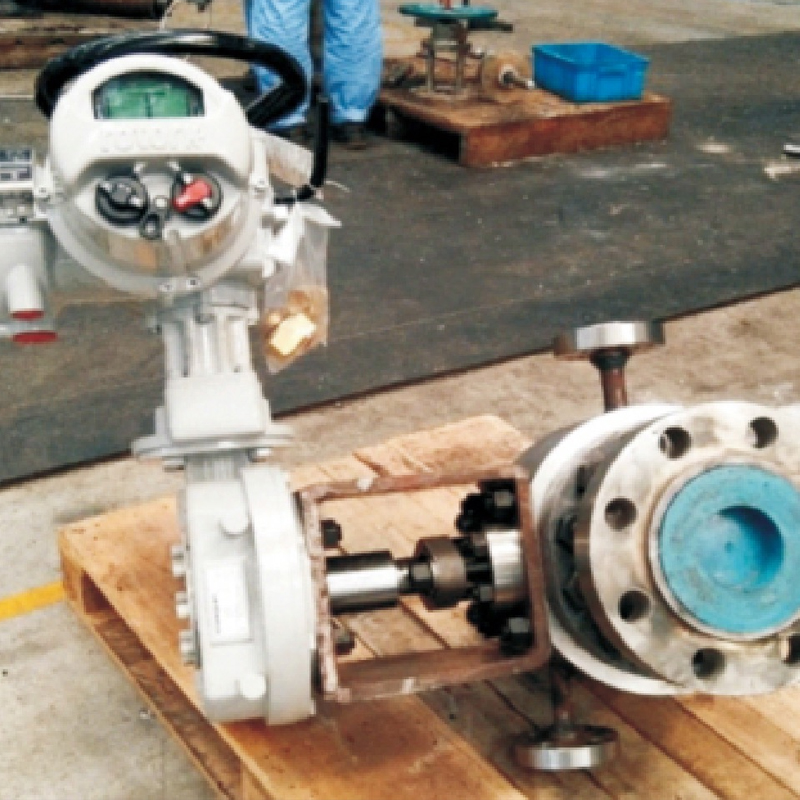

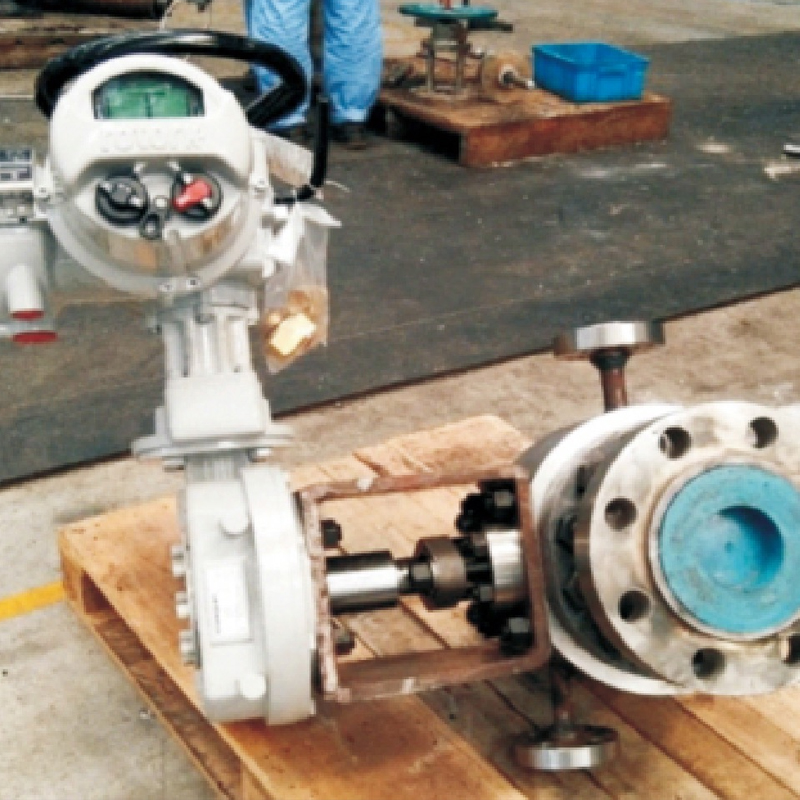

3. Select the Ball Valve according to the pipeline parameters: diameter specification (i.e. DN), interface mode

① Determine the diameter (DN) size according to the on-site pipeline inner diameter size or flow requirements.

② Interface mode. Generally, flange interface is selected for >DN50, and flange interface is selected for ≤DN50. It can be freely selected according to user needs.

4. Electrical selection: For voltage specifications, AC220V and DC24 should be preferred as it is more convenient.

5. Selection of Ball Valve based on pressure parameters: principles and structural varieties

①Nominal pressure: This parameter has the same meaning as other general valves, and is determined based on the nominal pressure of the pipeline.

②Working pressure: If the working pressure is low, the direct-acting or step-by-step direct-acting principle must be used; when the low working pressure difference is above 0.04Mpa, direct-acting, step-by-step direct-acting, and pilot-operated types can be selected.

6. Select auxiliary functions according to environmental requirements: explosion-proof, non-return, manual, waterproof fog, water spray, and diving

① Explosive environment: Ball Valve with corresponding explosion-proof levels must be selected (our company currently has: d II BT, ④d II CT5, Ex m I/II T4).

②When there is backflow of fluid in the pipe, you can choose our company`s OK71-N and OK72-N series Ball Valve with check function.

③When it is necessary to perform on-site manual operation of the Ball Valve, you can choose our company's OK71-S and OK72-S series Ball Valve with manual functions.

④ For outdoor installation or dusty situations, waterproof and dustproof varieties should be selected (protection level above IP54).

⑤A submersible Ball Valve must be used for fountains (protection level above IP68).