1) Adjustment function

① The valve is required to operate smoothly; ② The small opening has good adjustment performance; ③ Select the required flow characteristics; ④ Meet the adjustable ratio; ⑤ Small resistance and large flow ratio (the ratio of the rated flow parameter of the valve to the nominal diameter); ⑥Adjust the speed.

2) Leakage amount and cut-off pressure difference

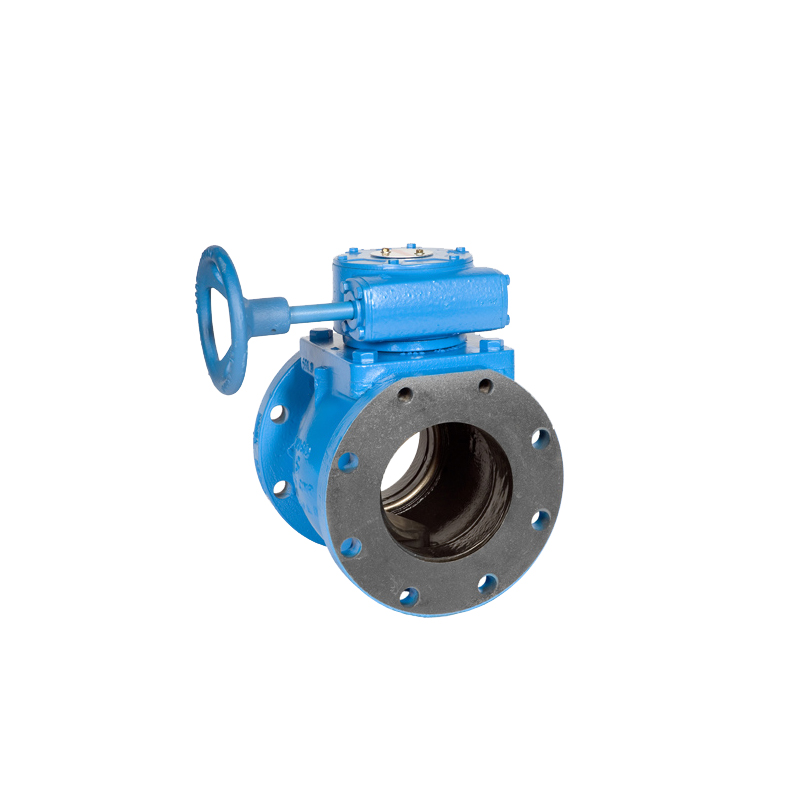

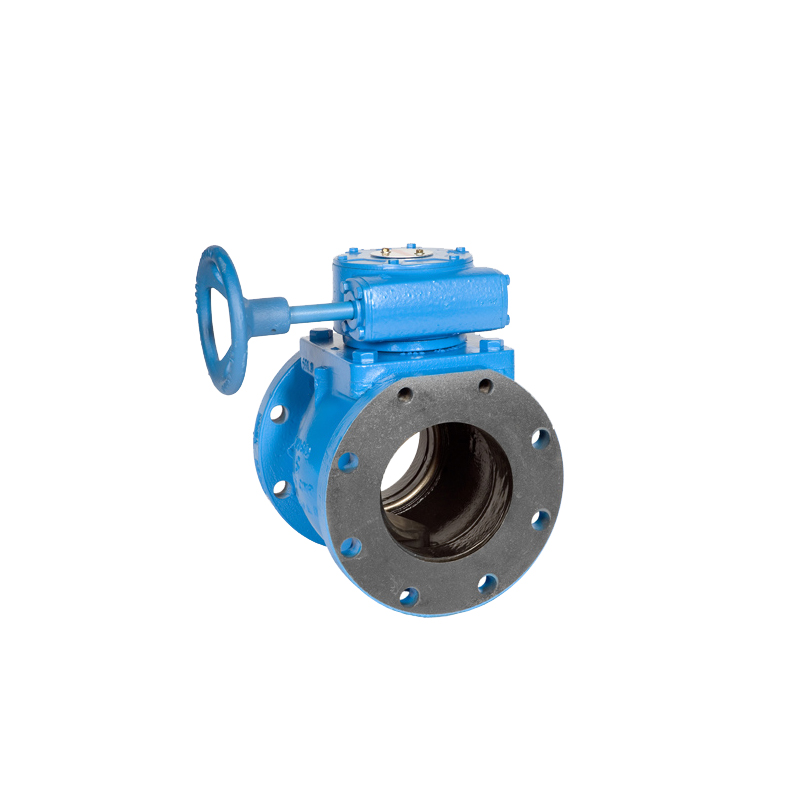

These are two factors that are inseparable and interrelated. The leakage amount should meet the process requirements, and there are measures to protect the reliability of the sealing surface; the cut-off pressure difference (pressure difference when the valve is closed) must be stated (unfortunately, this parameter is not included in the

Plug Valve calculation specifications of many design institutes) , so that the selected valve has enough output force to overcome it, otherwise it will cause the actuator to be larger or smaller.

3) Anti-blocking

Even if the medium is clean, there is still a problem of clogging. This is because unclean things in the pipeline are brought into the valve by the medium, causing blockage. This is a common fault, so the anti-blocking performance of the valve should be considered. Generally, quarter-turn Plug Valve have much better anti-blocking performance than straight-stroke Plug Valve, so the use of quarter-turn Plug Valve will become more and more common in the future.

4) Corrosion resistance

It includes resistance to erosion, cavitation, and corrosion. It mainly involves the selection of materials and the service life of the valve. At the same time, it also involves economic issues. The essence of this problem should be that the selected valve has good corrosion resistance and is reasonably priced. If you can choose a full PTFE valve, you should not choose a fully corrosion-resistant alloy valve; if you can choose an angle-shaped high-

Pressure Valve with better anti-cavitation effect and simple structure (satisfying a service life of about two years), you should not choose a complicated structure and expensive price. other high pressure valves.

5) Pressure resistance and temperature resistance

This involves the selection of the nominal pressure and operating temperature of the Plug Valve. In terms of pressure resistance, it is not difficult if the pressure is high, but the main reason is that the pressure difference will cause cavitation; in terms of temperature resistance, it is usually very easy to solve the problem below 450°C, and it is not difficult to solve the problem of 450 to 600°C, but when it reaches 600°C or above, The contradiction will become prominent; when the temperature is 80°C, it is usually not advisable to use soft sealing materials for shut-off Plug Valve, and hard-seal shutoff should be considered. The relationship between the working temperature, working pressure and nominal pressure of commonly used materials.

6) Weight and appearance

This question is very intuitive. Valves with good appearance and light weight must be popular among manufacturers. Here we need to change the prejudice that the Plug Valve is "big and thick". It is no big deal if it is heavier or looks worse. Now we attach great importance to it and propose that the Plug Valve should have the characteristics of miniaturization, lightness and instrumentation.