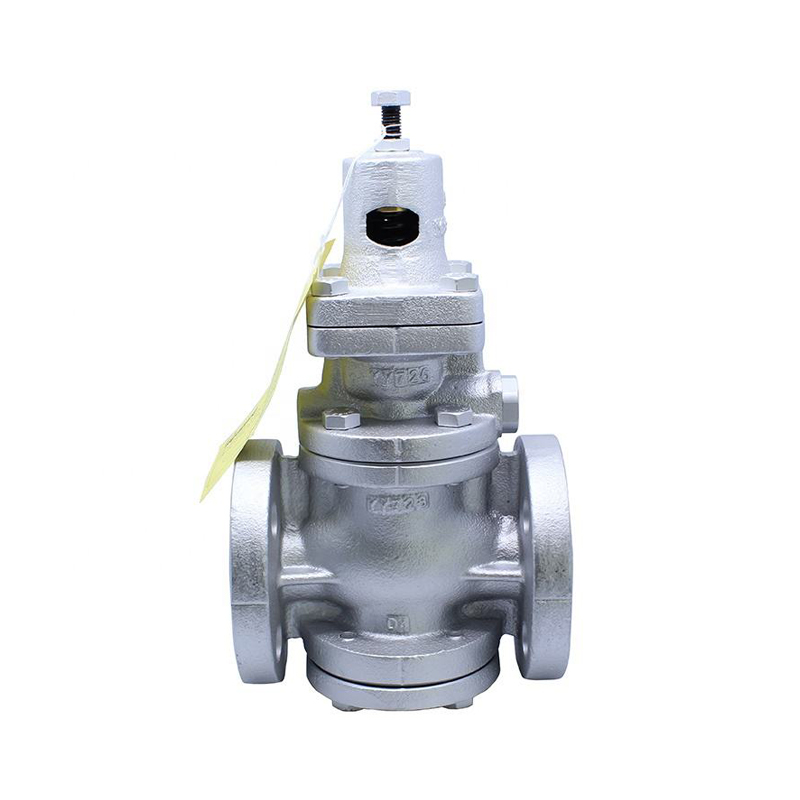

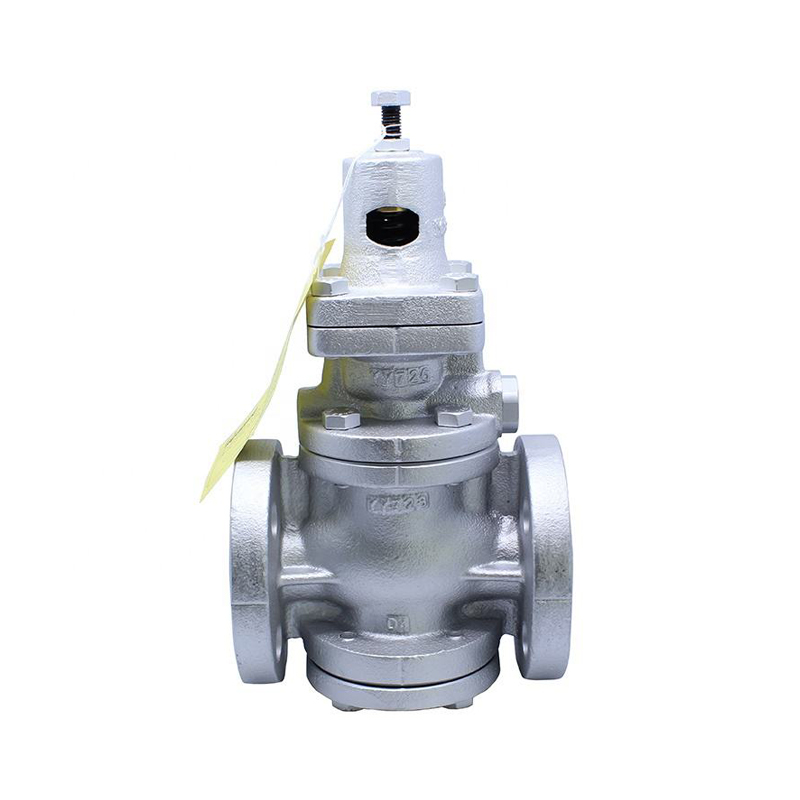

Pressure Relief Valve have been increasingly used in various industrial control systems due to their high control accuracy and convenient installation and debugging. However, during use, there are also some problems that bother on-site instrumentation personnel, namely the problem of valve internal leakage. Here we will discuss the common causes and solutions of internal leakage of Pressure Relief Valve, hoping to be of some help to the factory`s on-site maintenance personnel.

1. The zero position setting of the actuator is inaccurate and the fully closed position of the valve is not reached.

2. The valve is a push-down closing type. The thrust of the actuator is not large enough. When there is no pressure, it is easy to reach the fully closed position during debugging. However, when there is a downward push, it cannot overcome the upward thrust of the liquid, so it cannot close in place. Solution: Replace the actuator with a large thrust, or use a balanced valve core to reduce the unbalanced force of the medium.

3. Internal leakage caused by the manufacturing quality of the Pressure Relief Valve

Universal Valve manufacturers did not strictly

Control Valve materials, processing techniques, and assembly techniques during the production process, resulting in unqualified grinding of the sealing surface and incomplete removal of products with defects such as pitting and trachoma, resulting in internal leakage of the Pressure Relief Valve. Solution: Reprocess the sealing surface.

4. The control part of the Pressure Relief Valve affects the internal leakage of the valve.

The traditional control method of Pressure Relief Valve is through mechanical control methods such as valve limit switches and over-torque switches. Because these control components are affected by ambient temperature, pressure, and humidity, they cause valve positioning misalignment, spring fatigue, and uneven thermal expansion coefficients. and other objective factors, causing internal leakage of the Pressure Relief Valve. Solution: Readjust the limit.

5. Internal leakage caused by debugging problems of Pressure Relief Valve

Affected by the processing and assembly process, there is a common phenomenon that the Pressure Relief Valve cannot be opened electrically after being manually closed. If the stroke of the Pressure Relief Valve is adjusted smaller through the action position of the upper and lower limit switches, the Pressure Relief Valve will not close. or the valve cannot open. If the stroke of the Pressure Relief Valve is adjusted larger, the over-torque switch protection action will be caused. If the action value of the over-torque switch is adjusted larger, the deceleration transmission mechanism may be damaged or the over-torque switch may be damaged. Accidents that may damage valves or even burn out motors. In order to solve this problem, usually when debugging the Pressure Relief Valve, manually shake the Pressure Relief Valve to the bottom, then shake it in the opening direction to set the lower limit switch position of the electric door, and then open the Pressure Relief Valve to the fully open position to set the upper limit. Switch position, so that the Pressure Relief Valve will not be unable to open electrically after being manually closed tightly, so that the electric door can be opened and closed freely, but this will inadvertently cause internal leakage of the electric door. Even if the Pressure Relief Valve is adjusted ideally, since the action position of the limit switch is relatively fixed, the medium controlled by the valve will continuously wash and wear the valve during operation, which will also cause internal leakage caused by the valve not being closed tightly. Solution: Readjust the limit.

6. Incorrect selection causes cavitation corrosion of the valve and causes internal leakage of the Pressure Relief Valve.

Cavitation is related to the pressure difference. When the actual pressure difference ΔP of the valve is greater than the critical pressure difference ΔPc that causes cavitation, cavitation will occur. When the bubbles burst during the cavitation process, they release huge energy, which will cause damage to the valve seat and valve core. The throttling components such as these will have a huge destructive effect. If a general valve is operated under cavitation conditions for an additional three months or even less, the valve will suffer severe cavitation corrosion, causing the valve seat leakage to be as high as 30% of the rated flow rate. % or more, this is irreparable. Therefore, electric doors for different purposes have different specific technical requirements. It is crucial to reasonably select the Pressure Relief Valve according to the system process flow. Solution: Improve the process and use multi-stage pressure reduction or sleeve Universal Valve.

7. Internal leakage caused by medium erosion and aging of the Pressure Relief Valve

After the Pressure Relief Valve has been adjusted and operated for a certain period of time, due to cavitation of the valve, erosion of the medium, wear of the valve core and valve seat, aging of internal components, etc., the stroke of the Pressure Relief Valve will be too large and the Pressure Relief Valve will close. Failure to do so will cause the leakage of the Pressure Relief Valve to increase. As time goes by, the internal leakage of the Pressure Relief Valve will become more and more serious. Solution: Readjust the actuator and perform regular maintenance and correction.